Fermentation characteristic analyzerWSF-2000MH seriesIt is a method of effectively evaluating the fermentation ability of microorganisms such as yeast, the fermentation characteristics of culture media (dough, beer, etc.), and the fermentation conditions of samples by automatically continuously measuring and recording the total amount of gas and gas production rate of various samples during microbial fermentation. It can also monitor the fermentation process related to bread dough, alcohol brewing, bioethanol, and chemical processes such as BP (fermentation powder=chemical expansion agent) for a long time.

Measurement principle and composition:

During the fermentation process of the sample, gas is generated. The gas is displaced by gas-liquid through the water column pressure gauge, which drives the change of the water column in the pressure gauge. Then, the total volume and gas production rate of the gas are calculated based on the pressure detected by the pressure sensor and the temperature detected by the internal temperature sensor of the device.

Fermentation characteristic analyzerWSF-2000MHseriesAdvantages and Characteristics:

1. Multi sample measurement:WSF-2000MH-10W can measure 10 samples simultaneously;WSF-2000MH-20W can measure 20 samples simultaneously;

2. Each sample bottle can be controlled separately, measured separately, and the data curve recorded separately. The detection between each sample bottle does not affect each other;

3. Measure the total amount of gas generated, gas generation rate, and the amount of gas stored in the bread dough. The amount of gas generated can beExpressed in terms of switching volume (mL) and weight (g);

4. Fixed time interval, long-term detection: The time interval can be set between 5-120s (with 5s as the unit), and 5-120min (with 5min as the unit)Position). Second interval: up to 23 hours and 59 minutes; Interval: up to 90 days;

5. The standard sample bottle has a capacity of 225mL (the fabric is equivalent to 20g of wheat flour), and other sample bottles of different sizes can be selected

Conduct analysis of a large number of samples or trace amounts of samples;

6. Automatic calibration of temperature and pressure sensors;

7. Measurement standards for gas flow rate: in accordance with the National Institute of Metrology (NMIJ) of Japan;

8. Automatically store data lists and curve graphs, and export data information in CSV format;

9. Widely applicable and suitable for gas quantity detection in various gas production processes;

10. Small size, light weight, almost no consumables during the testing process, low maintenance cost;

11. The analysis software can control and record the fermentation process information of each sample bottle;

Application areas:

The changes in the amount of gas produced by microorganisms are important indicators of bacterial metabolism and activity. The measurement data of this device can be used for process control of various processes, exploration of optimal culture medium composition and fermentation conditions, etc.

Microorganisms - breeding of strains, baking products, alcohol brewing, soy sauce, food spoilage, industrial alcohol, and methane and hydrogen fields, such as wheat flour quality evaluation, brewing quality control, microbial strain screening, etc.

Chemical foaming agents - new product development and quality control in the fields of food expansion agents, foaming agents, detergents, bathing agents, and pharmaceuticals, such as expansion agents and foaming agents.

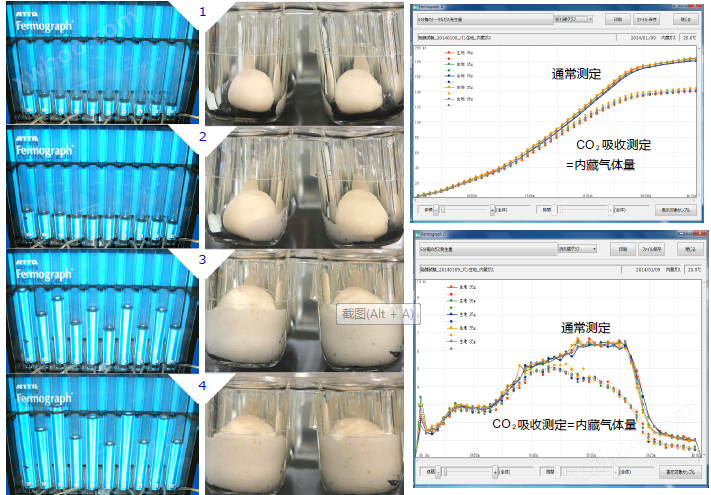

Experimental case:Monitoring of dough fermentation process